Whether you are packing an item by the case or individually, nothing safely moves a product from A to B more effectively and efficiently than corrugated packaging.

Corrugated packaging is a common packing choice due to its structural rigidity and cushioning qualities which helps to protect heavy or fragile contents from damage.

Corrugated packaging solutions from Colton Packaging are also super lightweight, which helps lower shipping costs and cut emissions. Plus, it can be recycled and renewed with ease – 96% of corrugated cardboard is recovered and recycled to make new boxes and other paper products.

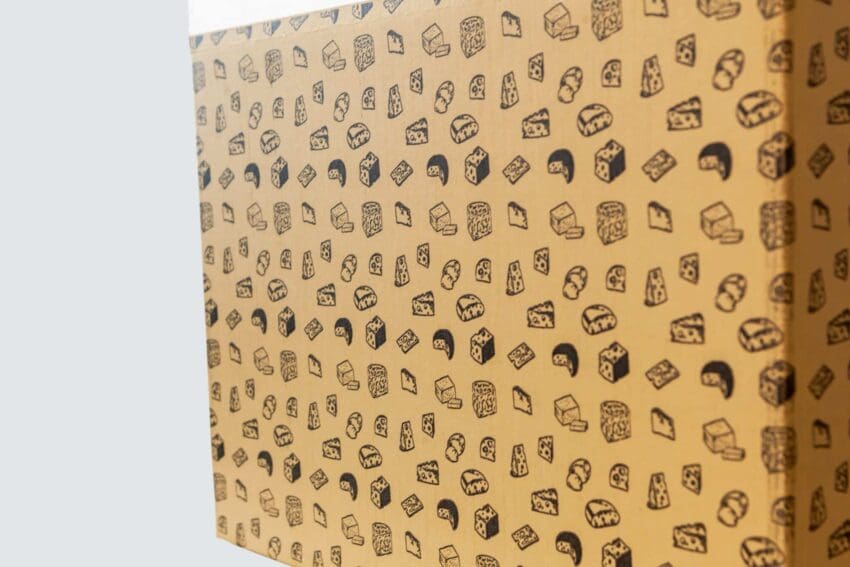

Corrugated packaging forms a blank canvas for custom artwork and branding. Because 97% percent of our products are made bespoke, we can help clients take advantage, working closely with them to develop a corrugated solution tailored to their needs.

Working from either a design brief or product, we can create corrugated packs using standard or modified FEFCO styles to sell your product with high-impact graphics that drive brand awareness and product preference.

Corrugated packaging helps to cushion products throughout the supply chain to protect against breakages in transit.

Corrugated packaging can be a critical supply chain efficiency tool for cost-effective product protection from products’ points of origin to their points of purchase and end-use.

Corrugated cardboard boxes help maximise every inch of shipment space making it an ideal shipping solution for a wide range of products in a variety of industries.